Deuterated mineral oil enables polymer research

The National Deuteration Facility has supported industry through the synthesis of deuterated mineral oil, which was supplied to Japanese chemical manufacturer Mitsui Chemicals. Mitsui Chemicals specialises in polymeric materials for packaging, appliances, construction and other applications.

- The aim of the work was to study the solubility of polymers in mineral oil. Mineral oil can be used as an additive to improve the properties of polymers.

- The deuterated mineral oil was used as a solvent for small-angle neutron scattering (SANS) on the QUOKKA beamline at the Australian Centre for Neutron Scattering (ACNS) to study samples of polyethylene polymer in deuterated mineral oil.

The QUOKKA beamline at the Australian Centre for Neutron Scattering

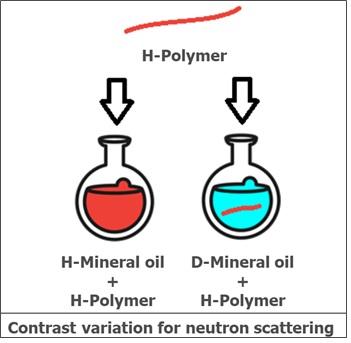

- Neutron scattering is a suitable technique for studying this system because it is composed of hydrocarbon materials. However, the hydrogen atoms from both the polymer and the oil will scatter neutrons strongly, making it difficult to see what the polymer is doing in the oil.

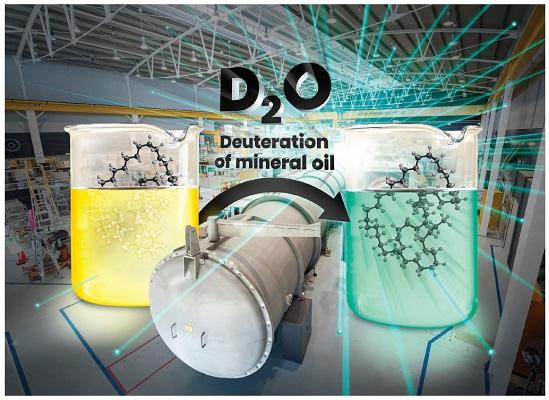

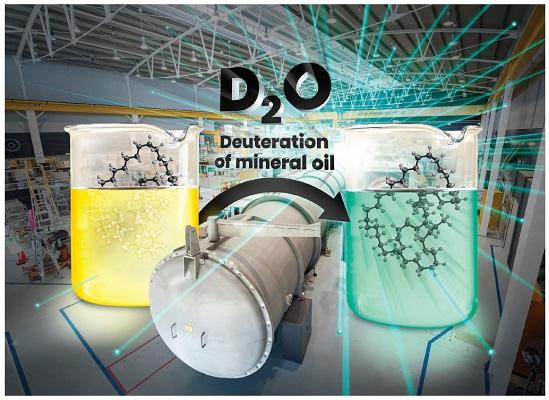

- The NDF devised a method of deuterating the mineral oil solvent on a multigram scale. This involved exchanging the hydrogen atoms of the mineral oil with deuterium atoms. Deuteration makes the mineral oil distinguishable from the polymer in the neutron scattering experiment so that the structure of the dissolved polymer can be observed.

- The SANS analysis of polyethylene polymer in deuterated mineral oil provided data to confirm that the mineral oil behaved as a theta solvent for polyethylene coils at 100 and 120oC . This means that the polymer coils act like ideal chains in solution, so the polymer coils are unperturbed in solution and their observed conformation at these temperatures is likely identical to pure molten polyethylene.

- This approach could be used to study the behaviour of any available hydrocarbon polymer sample mixed with a deuterated oil additive, to identify which oil additives provide desirable moulding and softness properties in polymer materials.

- Deuteration of oil solvent rather than polymer analyte may have applicability for other systems where deuteration of non-oil components is complicated. This potentially opens up avenues of enquiry for polymer manufacturing, healthcare, cosmetics and other areas. In addition, deuterated materials are more stable than their protonated analogues, and the use of deuterated mineral oils can be explored in applications where the higher thermo-oxidative resistance and storage stabilities afforded by deuteration is desired.

- This work was published in the RSC Journal Polymer Chemistry and featured on the inner cover.

https://doi.org/10.1039/D0PY00690D

Enquiries

Dr Tamim Darwish, NDF Leader

The National Deuteration Facility is partly supported by the National Collaborative Research Infrastructure Strategy – an initiative of the Australian Government.